Ideal for dry bulk material handling meyer made knife gates and slide gates are reliable and designed to isolate airlock feeders below from hoppers above.

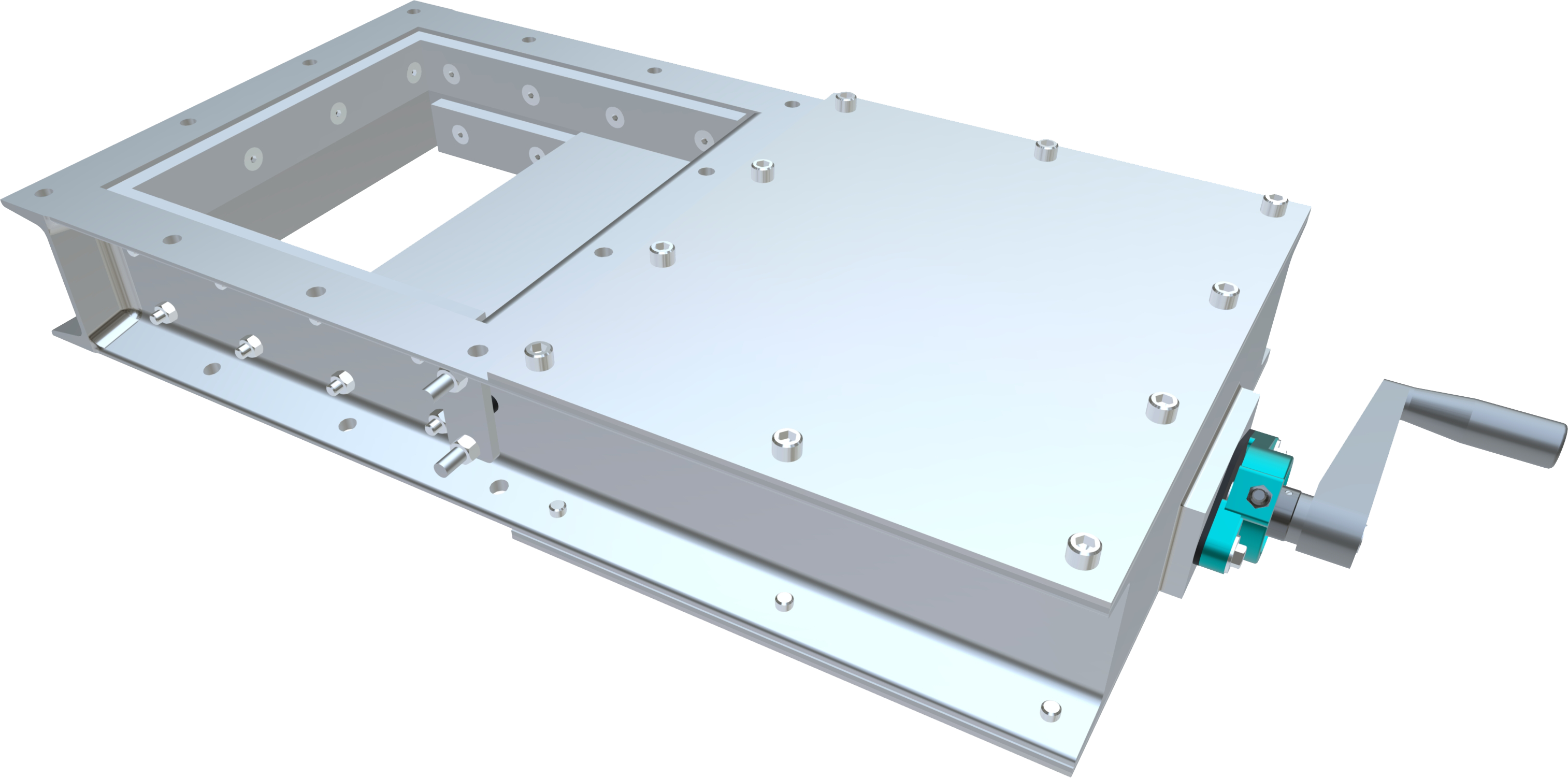

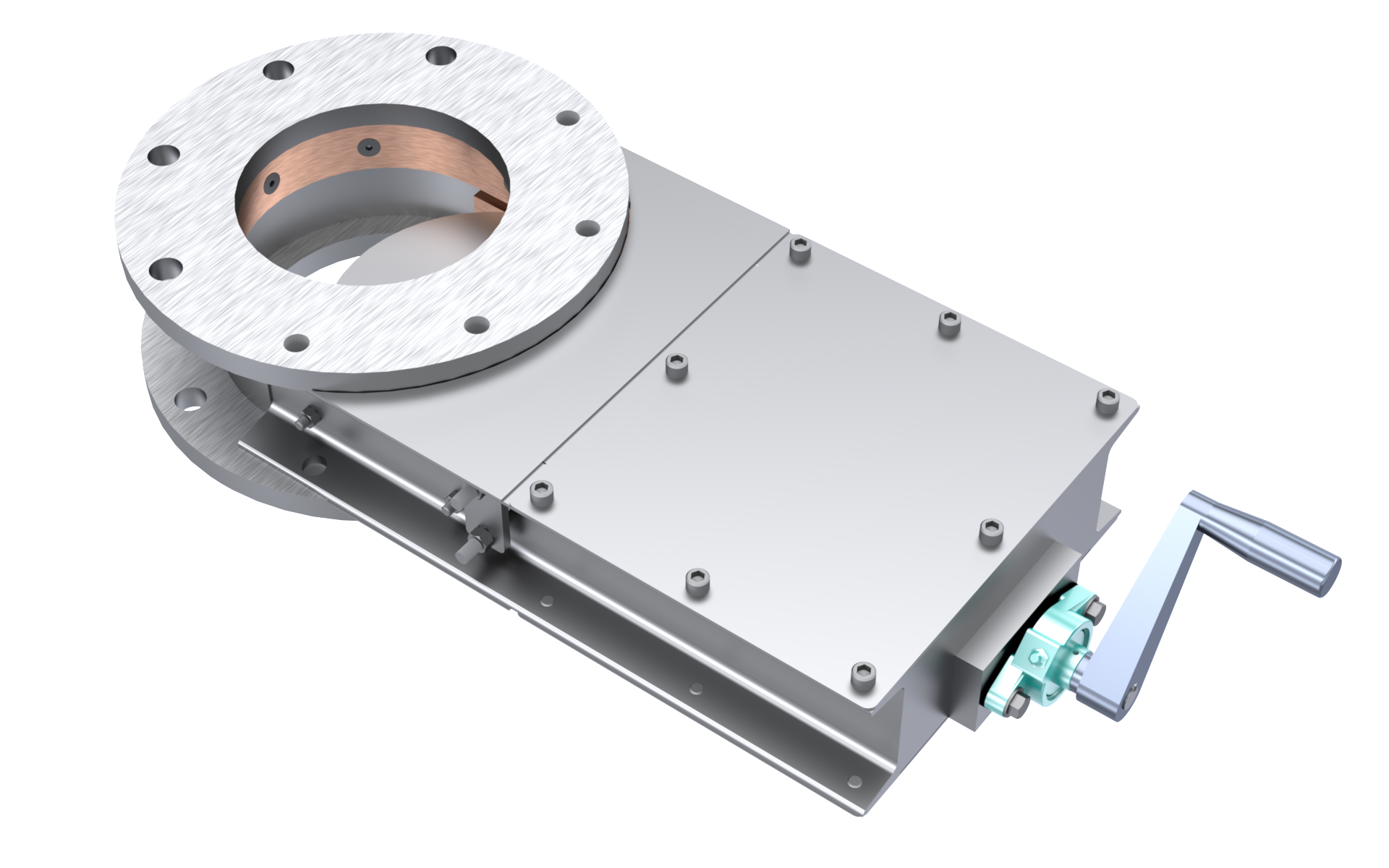

Manual slide gate valve design.

These gates deliver a positive shut off of material flow for service or replacement of the system rotary valve without the hopper being emptied.

Vortex valves serve many industries including chemical cement coal food.

Extend the service life of the valve and 2.

Ideal for handling dry bulk material in gravity flow dilute phase or dense phase pneumatic conveying applications.

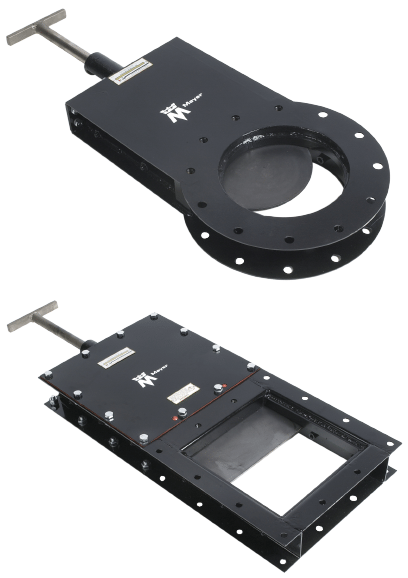

The knife gate and sliding gate valves help control gravity batch unloading when handling dry free flowing materials.

They are used for opening and closing product flow automatically to discharge the product to downstream equipment manually operated slidegate valves installed below silos or hoppers are generally used for maintenance operations of equipment like rotary valve screw feeder etc.

Knife and slide gate valves.

Once a knife gate s seals wear they start to leak and must be replaced.

Perform maintenance without taking the valve out of line.

Slide gate valve application examples silo discharge slide gate valves are generally actuated by pneumatic pistons.

The slide gate valve also self cleans material from the seat on each stroke of the slide plate to prevent bridging or packing of material.

The slide gate s hard polymer seals compensate for wear unlike the knife gate.

Wamgroup offers a large range of slide gate valves with innovative design features which is applicable wherever powders or granules are handled.

The maintenance slide gate is manually operated with a low profile.